3D Printed Digital Dentures

description1

Indications

3D Printed Digital Dentures are suitable for various clinical scenarios, including:

✔ Complete edentulism requiring full-arch rehabilitation

✔ Patients seeking expedited denture fabrication with fewer appointments

✔ Cases necessitating precise fit and aesthetics

✔ Situations where digital records facilitate easy reproduction or replacement

✔ Patients with sensitivities to traditional denture materials

Advantages

Enhanced Precision: Digital design ensures optimal fit, reducing the need for adjustments.

Accelerated Production: Streamlined workflows allow for denture delivery in as few as two appointments.

Cost-Effective: Reduced labor and material costs make these dentures an economical choice.

Consistent Quality: Digital archives enable easy replication and modifications, ensuring uniformity across multiple dentures.

Improved Patient Experience: Fewer visits and faster delivery enhance overall patient satisfaction.

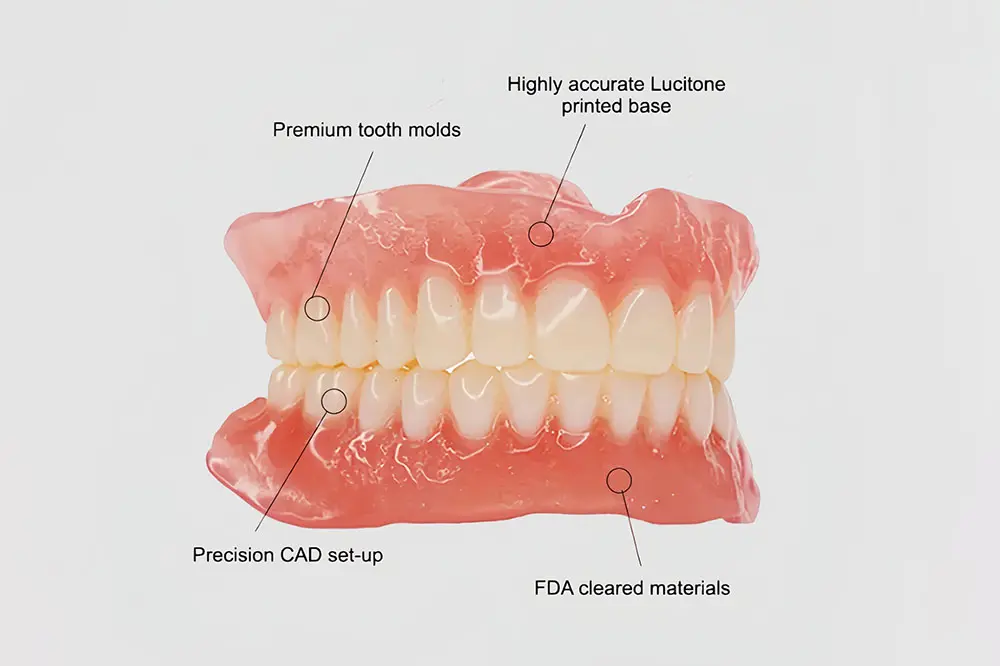

Material Composition

Biocompatible denture base resins (e.g., light-curing acrylics).

High-strength, wear-resistant denture teeth resins.

Optional nano-ceramic filled materials for enhanced aesthetics and durability.

Technical Specifications

| Fabrication via SLA or DLP 3D printing technologies | |

| Layer thickness: typically 50–100 microns | |

| CAD/CAM design using specialized dental software | |

| Post-processing includes curing, finishing, and polishing for optimal fit and appearance | |

| Turnaround Time | 3–5 working days |

| Lifetime (Warranty) | 3 years warranty (adjustments or remakes covered within warranty period) |

Before

After